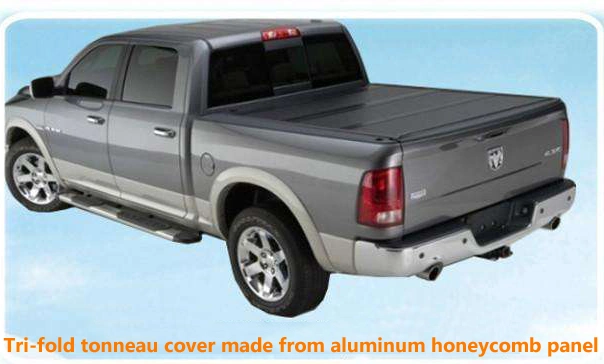

Aluminum honeycomb panel is a lightweight but strong metal composite panel, it's made from aluminum sheets and honeycomb structure aluminum core by sandwiched lamination. It's very popular for making pickup truck tri-fold covers and we've been exporting it to America, Japan, Russia, Europe etc.

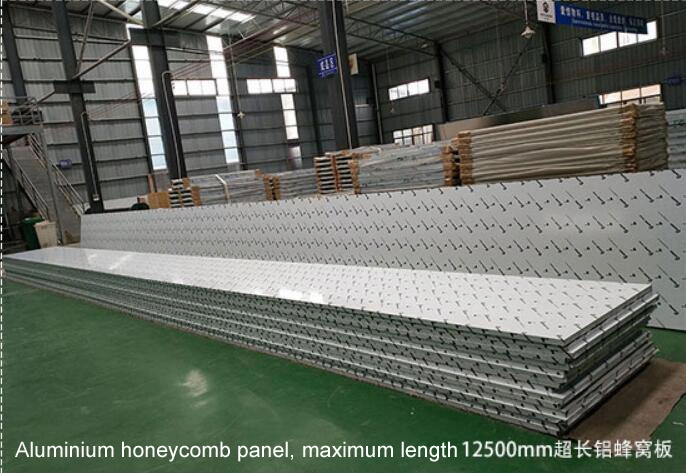

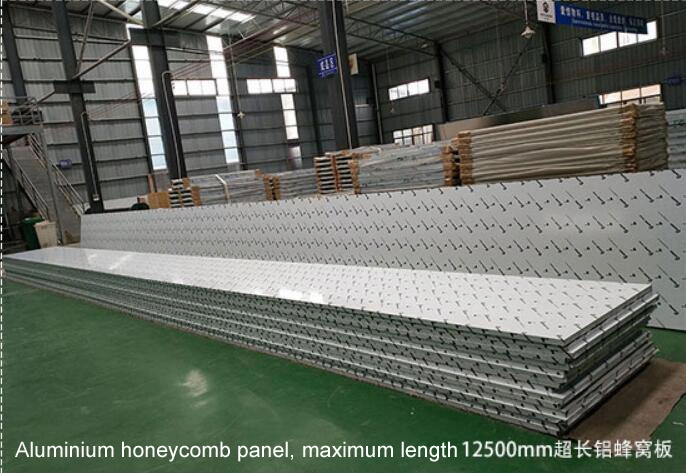

For building finish and decoration use, it's usually prefabricated as per framing system and installation drawings so that you can install the panels directly and quickly; for industrial use, we can produce and deliver it in large size (maximum 2500mm x 12500mm) and then the customers will further process it as per their purposes, we can also prefabricate the panels as per customer's designs and specifications.

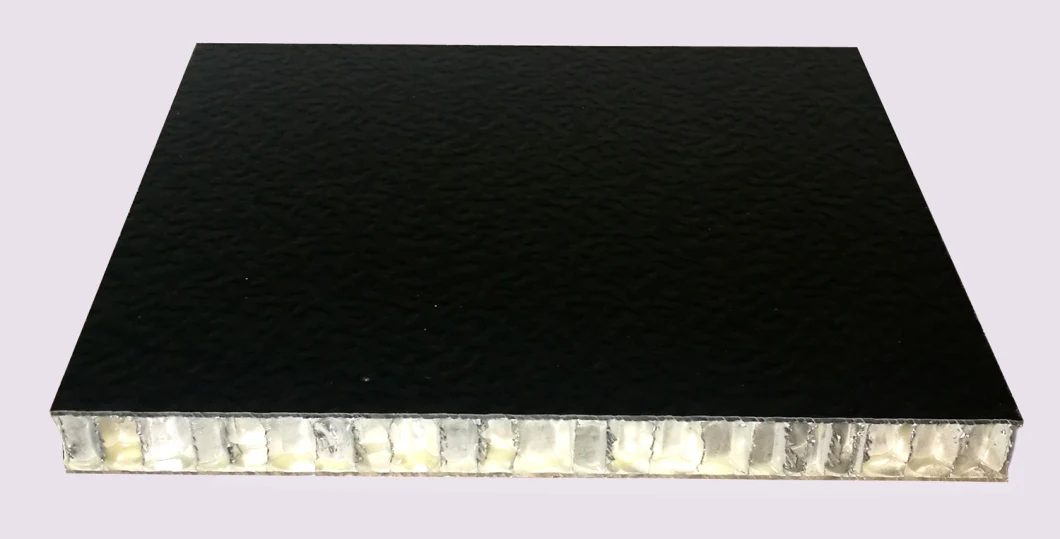

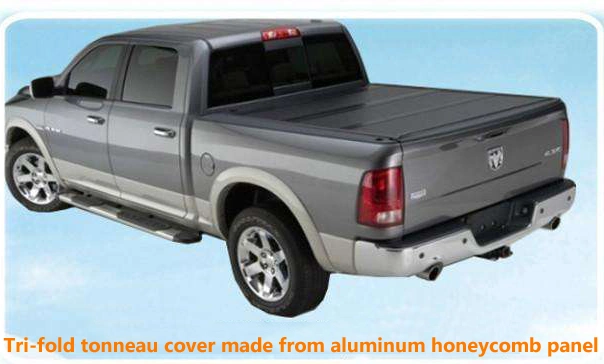

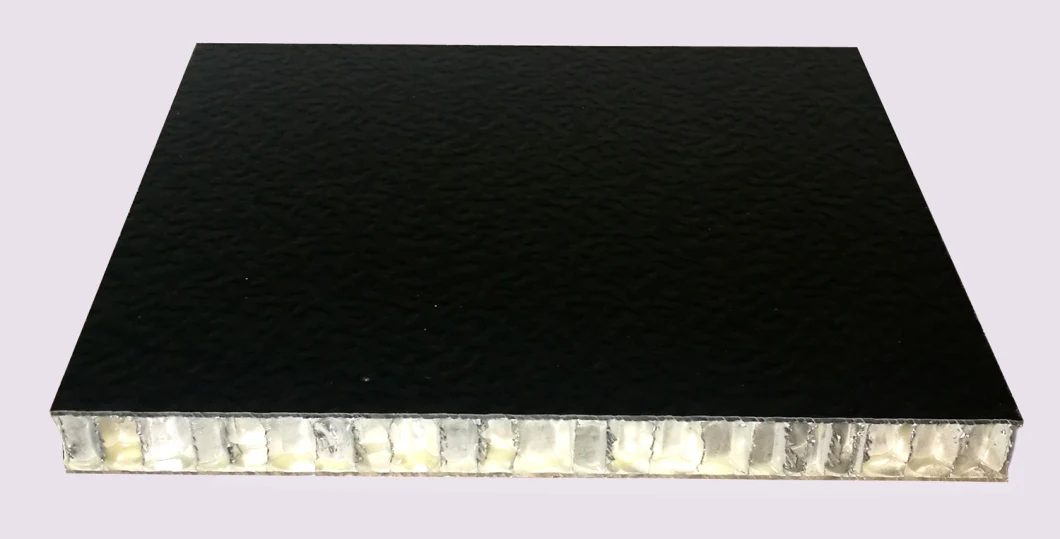

The embossed aluminum honeycomb panel with worm texture is very popular for making pickup truck tonneau covers because of its low weight but high stiffness and strength, we're producing thousands of covers monthly.

Specifications

Thickness of panel: 6mm, 8mm, 10mm, 15mm, 20mm, 25mm, 30mm, 35mm...........300mm.

Size: 1220x2440mm or customized sizes, maximum size 2500x12500mm

Weight: 3-15kg per square meter based on thickness 6mm~300mm

Strength>0.89MPa

Available colors: Solid colors, wood textures & colors, stone/marble/granite textures & colors

How the honeycomb panel is made

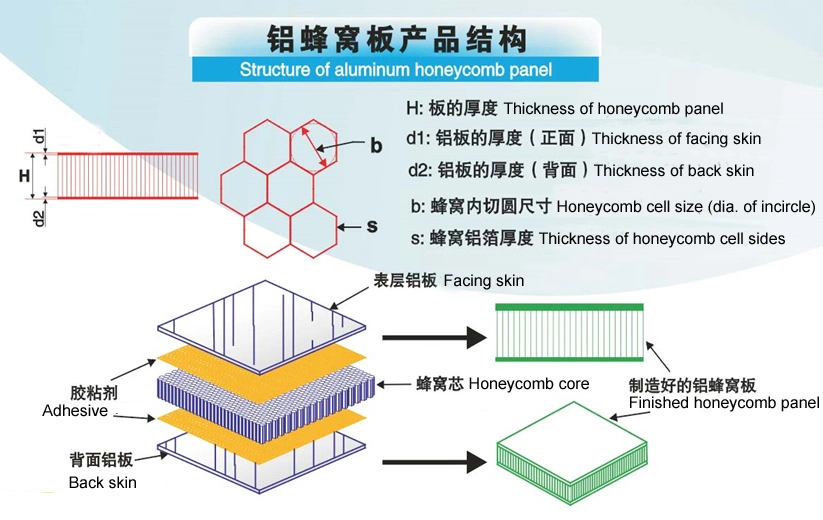

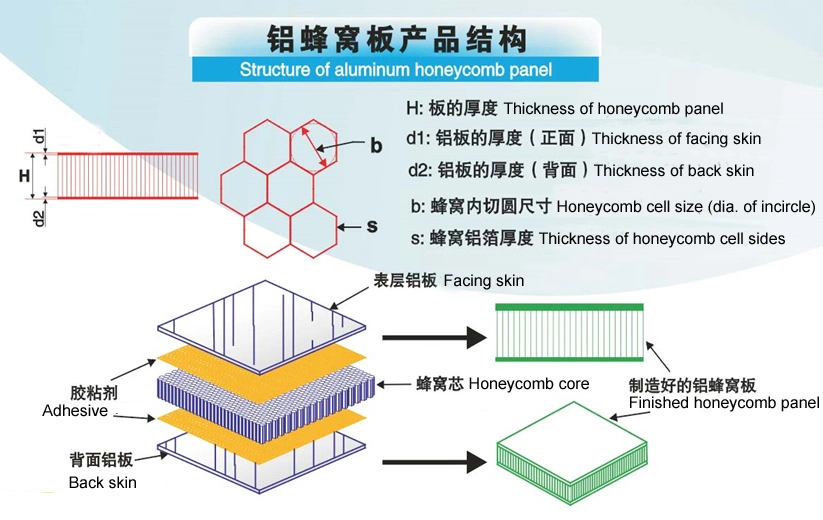

The honeycomb panel is typically made up of 5 layers by sandwich lamination: facing skin, adhesive, honeycomb core, adhesive and back skin.

Front and back skins: materials with high tensile and compression strength are best suited to being skins, i.e. aluminum, galvanized steel, stainless steel, fiberglass, HPL etc.

Adhesive varies widely by application: high strength or adhesion, high temperature, low temperature, etc.

Honeycomb Core: A variety of honeycomb cores are available as per design requirements to make various thickness of sandwich panels.

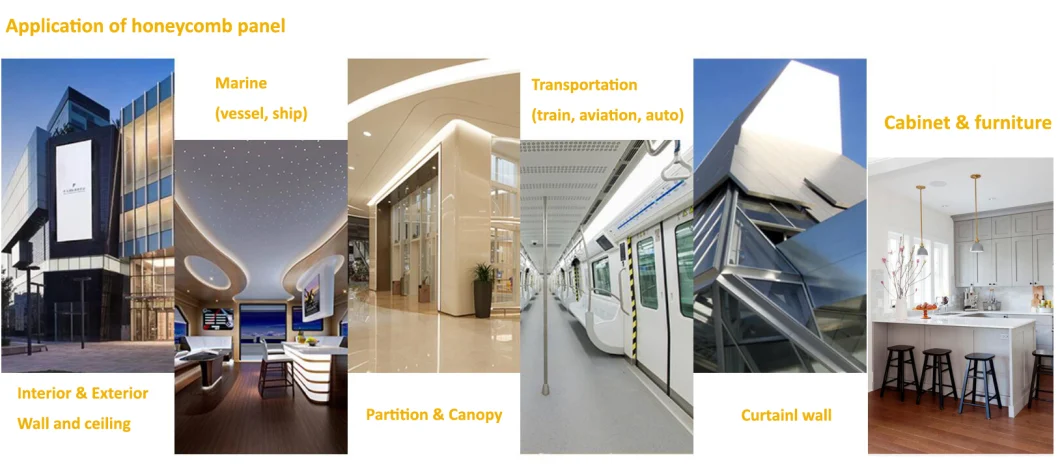

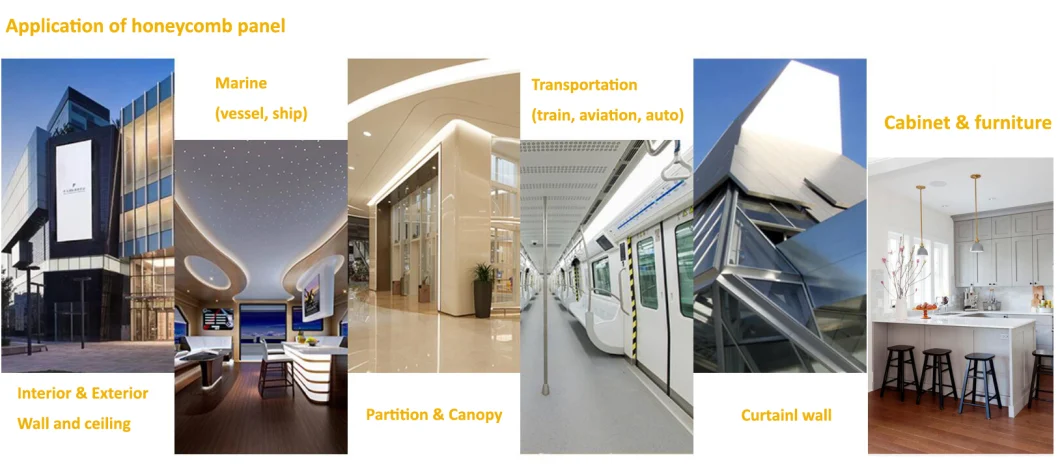

As a new type of Aluminum composite panel, the aluminium honeycomb sandwich panel is featured with light weight, high stiffness and strength, good flatness and resistance, economical costs and easy for fabrication and installation. Aluminum honeycomb panel is very suitable and popular for building decoration (walls, ceilings, canopies, partitions, roofs etc.) and tables, cabinets, shelves, furniture, boards of automobiles or vessels etc.

The aluminum sandwich panel is made from coated aluminum sheets with solid colors or with stone/marble/granite textures & colors and honeycomb structure aluminium foil core by sandwich lamination, also called as aluminum honeycomb panel. The colors can be customized as per design requirements. The aluminum honeycomb panel with 3D wood textures and colors is very good alternative for wood panel to make lightweight, strong and durable applications.

Advantages

Aluminum honeycomb panel is a lightweight strong sandwich composite laminated panel, the weight of aluminum honeycomb panel is only 3kg to 10kg per square meter for panel thickness of 6mm to 300mm and the regidity is more than 1.5kN.sqm/m , with prefabrication and assembly of fittings according to framing system, you can easy install the honeycomb panels to the buildings, also very popular for envelope and decoration of interior & exterior walls, partitions, facades, ceiling and canopies. Aluminum honeycomb panel or stainless steel honeycomb sandwich panel is the best alternative materials for single aluminum panel or stainless steel panel because of the competitive cost and much lower weight, much better flatness and much higher strength. It's a green and environment-friendly building and decoration material, trending the construction and decoration industry.

Features

• Low weight and competitive cost

• High stiffness and strength

• Easy to fabricate and install

• Recyclable

• PVDF coating or anodized finish aluminum facing skins for good anti-corrosion performance and high resistance.

• Aluminium facing skins are available in a range of thicknesses from 0.5mm to 3.0mm as per design requirements

• Panels can be produced with different aluminum sheet thicknesses on front and back faces and panel thicknesses as per custom design requirements for weight, strength and installation.

• Aluminum faced panels are chemically cleaned: suitable for painting or the application of decorative laminates

• Brushed and anodised aluminum finishes are also available

• Aluminum honeycomb cell size is 4mm to 8mm as request.

• Wide selection of Joiners &Assembly Accessories are available.

Application

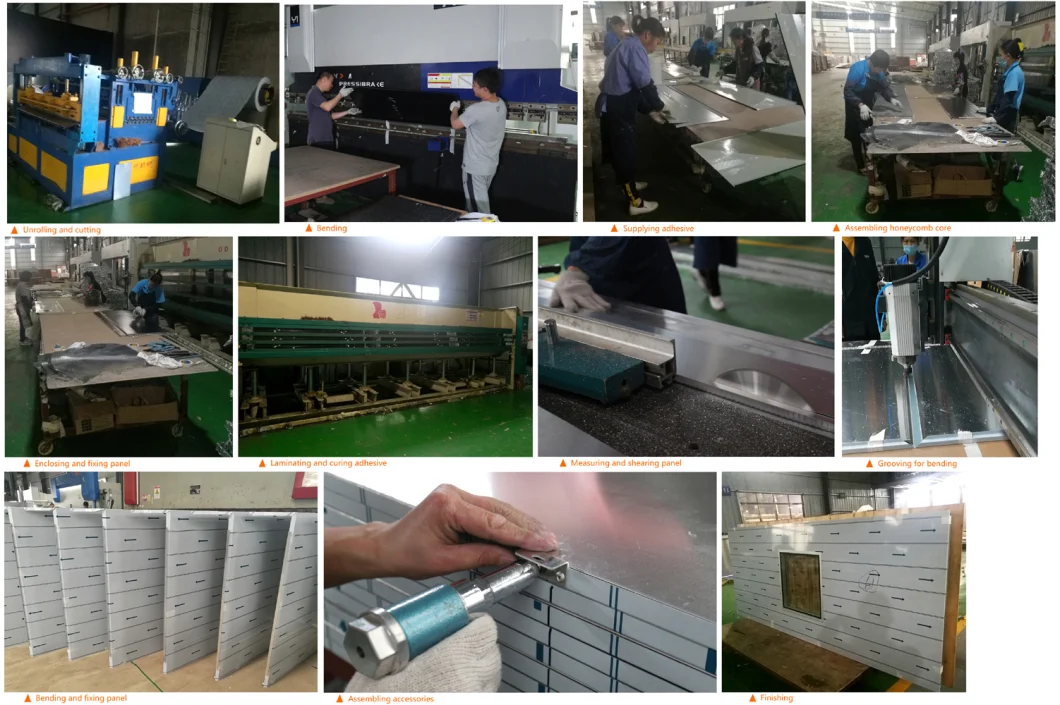

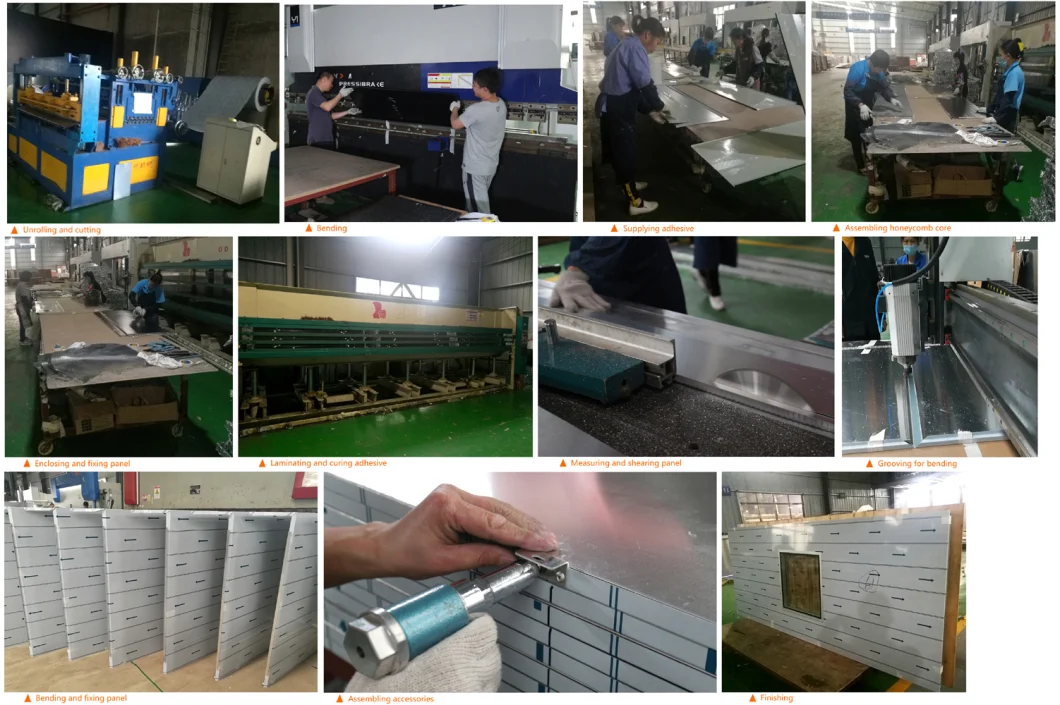

Manufacturing Procedure

Roller coating or anodized surface, unrolling and cutting aluminium sheets, punching corners, bending aluminum sheets, supplying adhesive (glue) to front and back panels, unfolding aluminum honeycomb core, cutting out and putting honeycomb core into back panel, putting front panel, fixing front and back panels, putting sandwich panels into laminating machine, laminating, checking and finishing. To make panels ready for installation (for architecture cladding and decoration), asembling accessories to the panels and then packing for shipping.

Packing

For building finish and decoration use, it's usually prefabricated as per framing system and installation drawings so that you can install the panels directly and quickly; for industrial use, we can produce and deliver it in large size (maximum 2500mm x 12500mm) and then the customers will further process it as per their purposes, we can also prefabricate the panels as per customer's designs and specifications.

The embossed aluminum honeycomb panel with worm texture is very popular for making pickup truck tonneau covers because of its low weight but high stiffness and strength, we're producing thousands of covers monthly.

Specifications

Thickness of panel: 6mm, 8mm, 10mm, 15mm, 20mm, 25mm, 30mm, 35mm...........300mm.

Size: 1220x2440mm or customized sizes, maximum size 2500x12500mm

Weight: 3-15kg per square meter based on thickness 6mm~300mm

Strength>0.89MPa

Available colors: Solid colors, wood textures & colors, stone/marble/granite textures & colors

How the honeycomb panel is made

The honeycomb panel is typically made up of 5 layers by sandwich lamination: facing skin, adhesive, honeycomb core, adhesive and back skin.

Front and back skins: materials with high tensile and compression strength are best suited to being skins, i.e. aluminum, galvanized steel, stainless steel, fiberglass, HPL etc.

Adhesive varies widely by application: high strength or adhesion, high temperature, low temperature, etc.

Honeycomb Core: A variety of honeycomb cores are available as per design requirements to make various thickness of sandwich panels.

As a new type of Aluminum composite panel, the aluminium honeycomb sandwich panel is featured with light weight, high stiffness and strength, good flatness and resistance, economical costs and easy for fabrication and installation. Aluminum honeycomb panel is very suitable and popular for building decoration (walls, ceilings, canopies, partitions, roofs etc.) and tables, cabinets, shelves, furniture, boards of automobiles or vessels etc.

The aluminum sandwich panel is made from coated aluminum sheets with solid colors or with stone/marble/granite textures & colors and honeycomb structure aluminium foil core by sandwich lamination, also called as aluminum honeycomb panel. The colors can be customized as per design requirements. The aluminum honeycomb panel with 3D wood textures and colors is very good alternative for wood panel to make lightweight, strong and durable applications.

Advantages

Aluminum honeycomb panel is a lightweight strong sandwich composite laminated panel, the weight of aluminum honeycomb panel is only 3kg to 10kg per square meter for panel thickness of 6mm to 300mm and the regidity is more than 1.5kN.sqm/m , with prefabrication and assembly of fittings according to framing system, you can easy install the honeycomb panels to the buildings, also very popular for envelope and decoration of interior & exterior walls, partitions, facades, ceiling and canopies. Aluminum honeycomb panel or stainless steel honeycomb sandwich panel is the best alternative materials for single aluminum panel or stainless steel panel because of the competitive cost and much lower weight, much better flatness and much higher strength. It's a green and environment-friendly building and decoration material, trending the construction and decoration industry.

Features

• Low weight and competitive cost

• High stiffness and strength

• Easy to fabricate and install

• Recyclable

• PVDF coating or anodized finish aluminum facing skins for good anti-corrosion performance and high resistance.

• Aluminium facing skins are available in a range of thicknesses from 0.5mm to 3.0mm as per design requirements

• Panels can be produced with different aluminum sheet thicknesses on front and back faces and panel thicknesses as per custom design requirements for weight, strength and installation.

• Aluminum faced panels are chemically cleaned: suitable for painting or the application of decorative laminates

• Brushed and anodised aluminum finishes are also available

• Aluminum honeycomb cell size is 4mm to 8mm as request.

• Wide selection of Joiners &Assembly Accessories are available.

Application

- Architectural wall Cladding and decoration

- Architectural Rainscreen Facades and canopies envelope.

- Lightweight interior and exterior architectural panels.

- Aerospace, Marine & Transport Flooring, ceilings, Walls & Partitions

- Silk Screen Printing Tables, doors and cabinets

- CNC Vacuum Bases

- Lightweight Floors, Walls, partitions, canopies, Ceilings, roofs etc.

- Special Purpose Panel Design.

Manufacturing Procedure

Roller coating or anodized surface, unrolling and cutting aluminium sheets, punching corners, bending aluminum sheets, supplying adhesive (glue) to front and back panels, unfolding aluminum honeycomb core, cutting out and putting honeycomb core into back panel, putting front panel, fixing front and back panels, putting sandwich panels into laminating machine, laminating, checking and finishing. To make panels ready for installation (for architecture cladding and decoration), asembling accessories to the panels and then packing for shipping.

Packing